Data Preparation for Metal Additive Manufacturing

Description

Achieve your full potential with our Certificate Program in Data Preparation for Metal Laser Powder Bed Fusion. Designed for data preparation engineers, machine operators, and application engineers, this immersive program focuses on mastering one of the most critical steps in the additive manufacturing process.

In AM, the success of the entire process chain relies on effective data preparation, as it directly impacts production quality and efficiency. Mastering this skill can make the difference between success and failure in AM projects.

Through our specialized courses, you’ll gain the skills to optimize data preparation for metal AM, streamline production processes, and advance your career in the growing field of additive manufacturing.

Program Benefits

Gain a thorough understanding of the metal Laser Powder Bed Fusion (LPBF) data preparation workflow.

Gain a thorough understanding of the metal Laser Powder Bed Fusion (LPBF) data preparation workflow.-

Engage directly with EOS engineers during insightful expert sessions.

Engage directly with EOS engineers during insightful expert sessions. -

Apply theoretical knowledge through hands-on tasks with personalized feedback from EOS engineers.

Apply theoretical knowledge through hands-on tasks with personalized feedback from EOS engineers. -

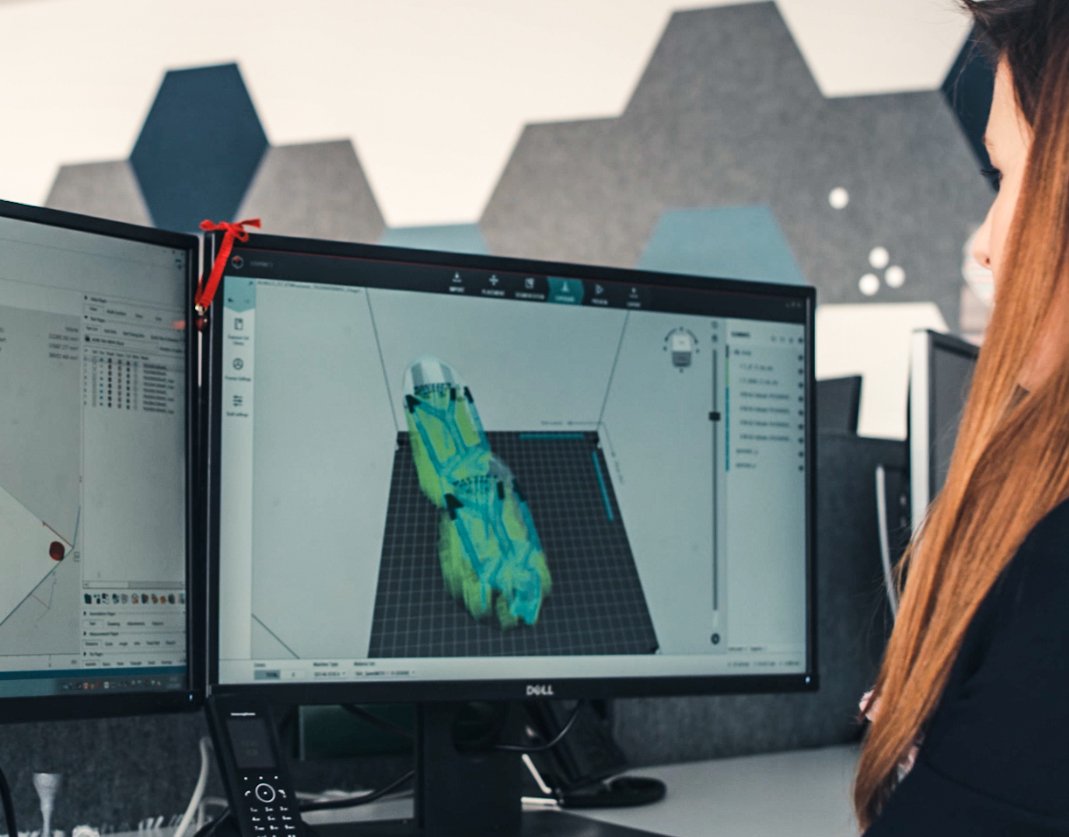

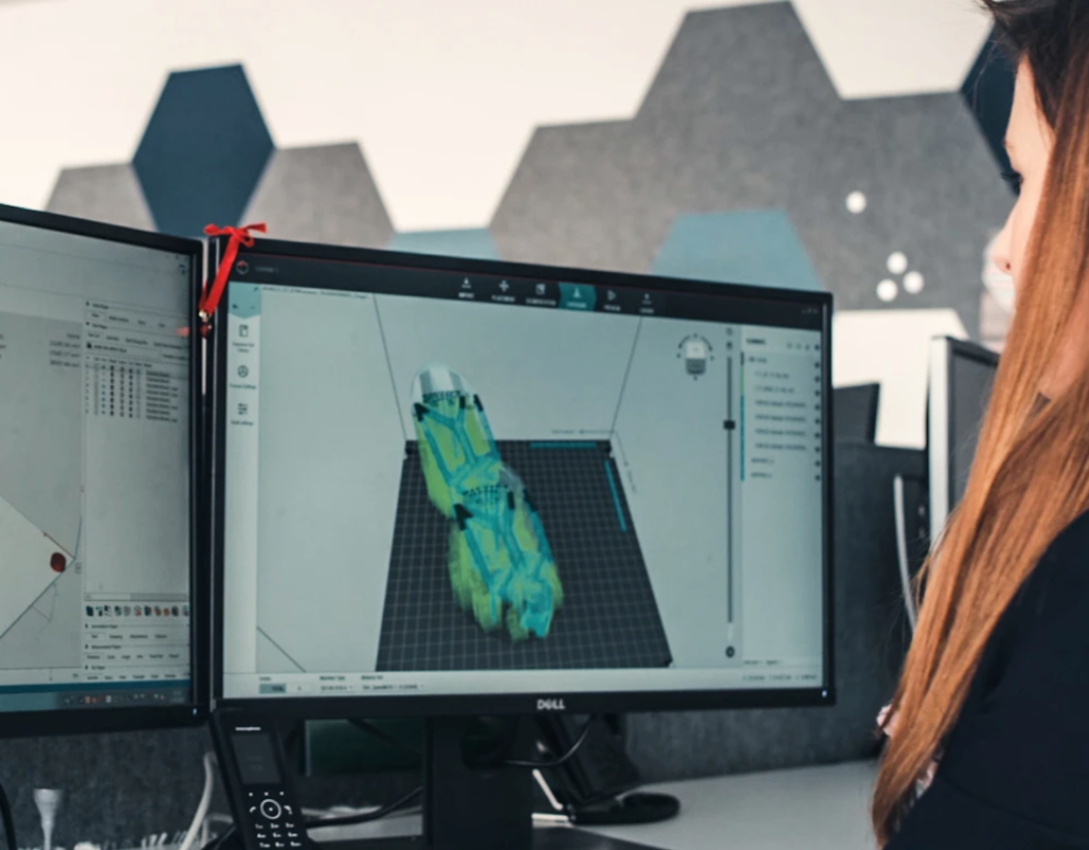

Get access to training licenses for EOSPRINT 2 and Materialise Magics software.

Get access to training licenses for EOSPRINT 2 and Materialise Magics software. -

Build a robust network within the additive manufacturing (AM) expert community.

Build a robust network within the additive manufacturing (AM) expert community. -

Access continually updated content for staying at the forefront of industry advancements.

Access continually updated content for staying at the forefront of industry advancements. -

Benefit from safer, faster, and more stable build jobs moving forward.

Benefit from safer, faster, and more stable build jobs moving forward. -

Obtain a recognized certificate from the industry leader in AM.

Obtain a recognized certificate from the industry leader in AM.

Learning Objectives

Upon completing this certificate program, participants will be able to:

-

Understand EOSPRINT and Materialise Magics.

Understand EOSPRINT and Materialise Magics. -

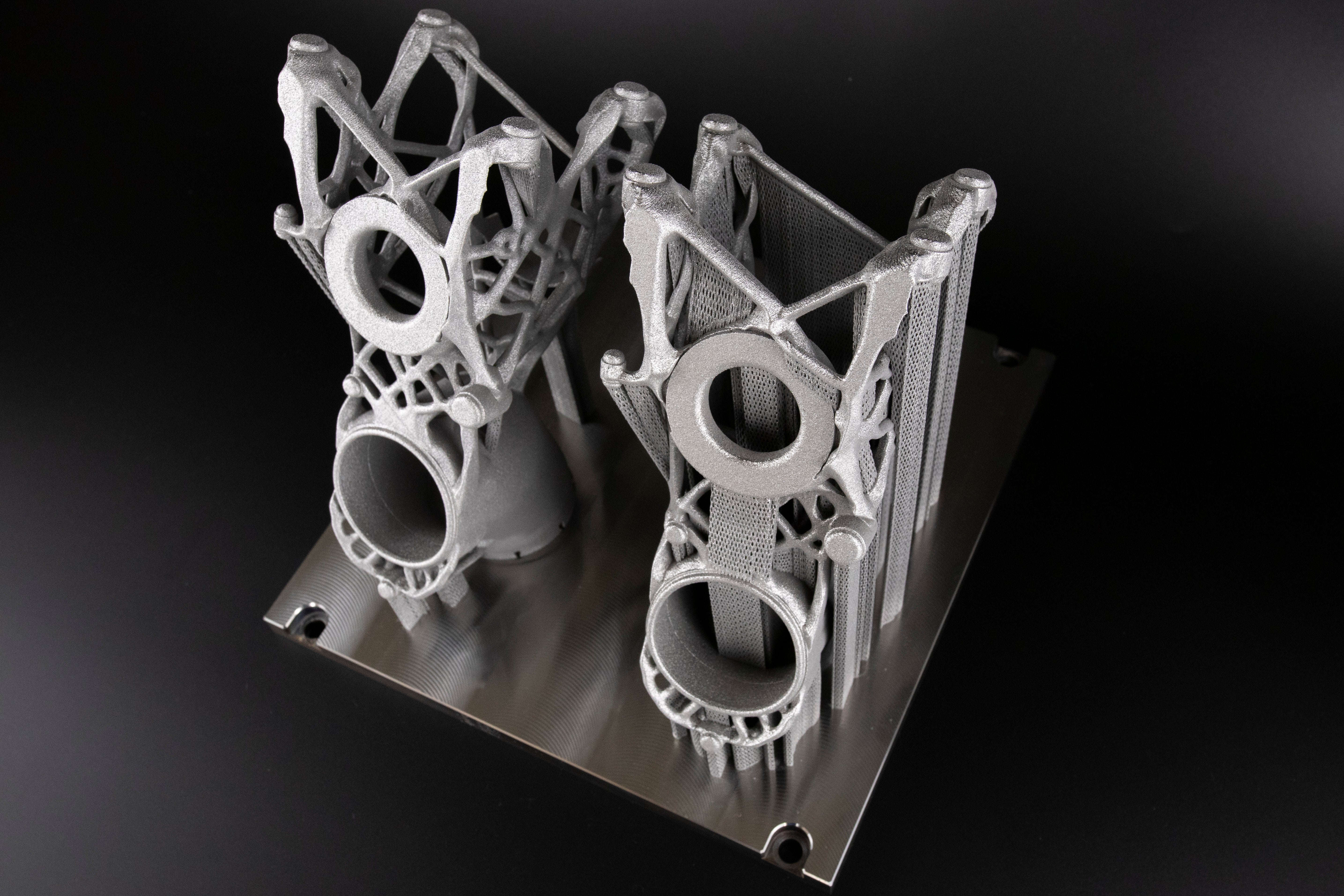

Apply different support structures to parts.

Apply different support structures to parts. -

Create build job files for EOS metal systems.

Create build job files for EOS metal systems. -

Orient parts based on printability, cost, and quality factors.

Orient parts based on printability, cost, and quality factors. -

Apply all of the above simultaneously to improve their parts.

Apply all of the above simultaneously to improve their parts.

Course Overview

Your training is split into five phases:

- Introduction to the Program: Brief welcome and overview of the Data Preparation Metal Certificate Program.

- Program Objectives: High-level discussion on what students will learn throughout the program, including key skills and knowledge areas.

- Data Preparation Workflow Efficiency: Guidelines for reducing material usage through smart support design and part orientation, contributing to cost savings and environmental sustainability.

- Support generation workflow: Learn the process of generating and editing supports

- Software activation and installation: Learn the essentials of activating Materialise Magics, including software installation, obtaining license key, and navigating the license wizard.

- User interface: Explore the user interface of Materialise Magics, mastering functionalities such as customizing your library, utilizing the context menu, leveraging quick search, understanding view functionalities, and using marking tools for enhanced efficiency.

- Build Preparation: Acquire critical skills for preparing your builds in Materialise Magics, including importing parts, applying basic orientation techniques, and generating supports to ensure part quality and process efficiency.

- Software Introduction: Learn how to activate and install EOSPRINT 2 software, setting the foundation for operating EOS machines and starting your additive manufacturing projects on the right foot.

- Interface Overview: Navigate the EOSPRINT 2 user interface with ease, learning to efficiently access and utilize its comprehensive features for an optimized workflow.

- Basic Functionality: Master the core functionalities of EOSPRINT 2, including file management, setting adjustments, and software navigation to enhance your operational efficiency.

- Build Preparation: Develop the expertise to prepare build jobs in EOSPRINT 2, from importing and manipulating data files to finalizing the build setup for execution.

- Case Study: Learn through practical case studies that demonstrate how to apply EOSPRINT 2 in real-world scenarios, solving common challenges in metal additive manufacturing.

- Conclusion: Conclude your EOSPRINT 2 training with a comprehensive overview, solidifying your understanding of the software's capabilities and preparing you to apply your new skills to achieve remarkable results in your additive manufacturing projects.

Final Assessment

- Hands-on Experience: This final assessment offers hands-on experience, cementing the learners' understanding and proficiency in data preparation for metal additive manufacturing.

- Detailed Instructions: Participants will be provided with detailed instructions to guide them through the completion of their assignments, ensuring clarity and direction.

- Necessary Files Provided: All necessary files required to complete the assignments will be supplied to the participants, facilitating a smooth and informed learning experience.

- Instructor Grading: Solutions submitted by the learners are graded by the instructor, providing valuable feedback and insights into their proficiency and areas for improvement.

Expert Session Overview

- Duration: Two-hour comprehensive Expert Session

- Pre-condition: Participants must have completed all online coursework and submitted the Instructor Graded Assessment to qualify for the Expert Session.

- Scope: Opportunity for participants to ask questions and discuss open points noted during or after the e-learning component of the course.

FAQ

Every AM Academy course offers a rich learning experience

Real World Experience

Explore and assess real-world projects with case studies and portfolio examples.

Community & Experts

Receive valuable feedback from tutors and other learners in peer reviews, Q&A sessions and discussion groups.

Hands On Practice

Gain vital experience in methodologies and processes while working on practical tasks, exercises, and tools.

Flexible Learning

Learn at your own pace and access modules on the go with our self-study online classes.

Find Out More

Want to learn more about this certificate program or other courses? Get in touch with our AM Academy experts to schedule a call today.

Book a free consultation